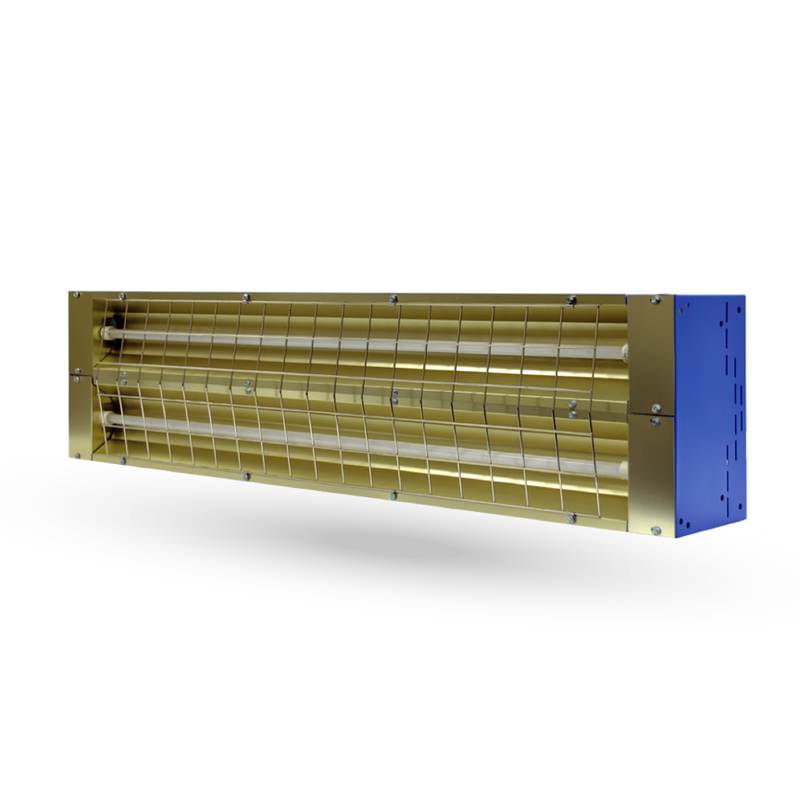

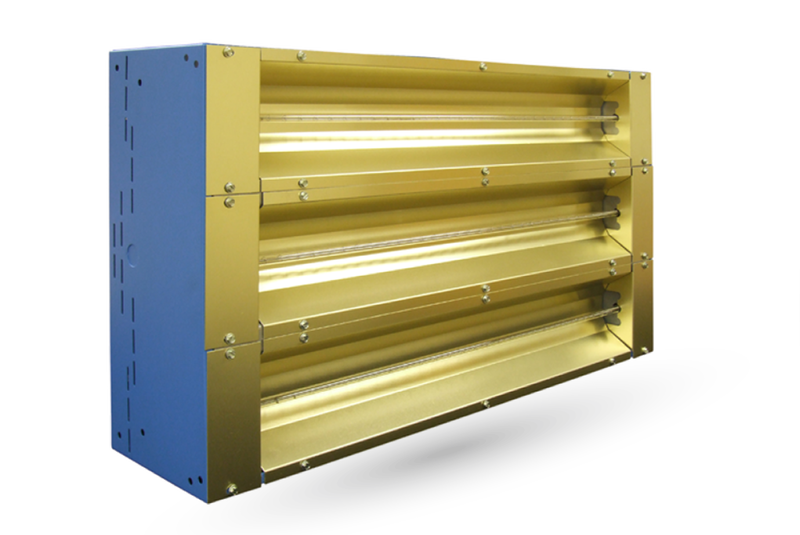

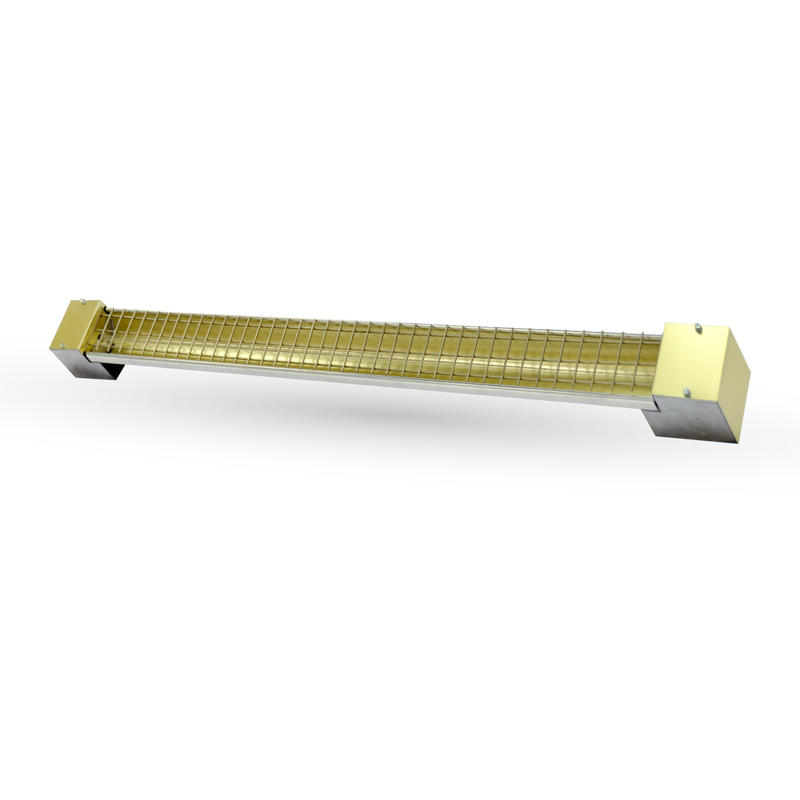

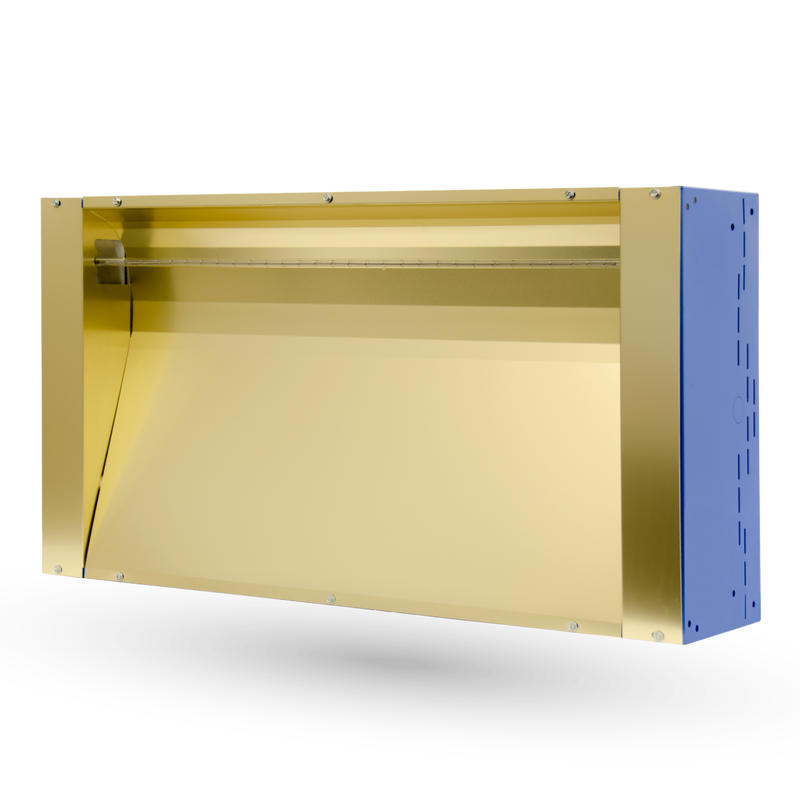

900 Series / Electric Infrared Modular Sections

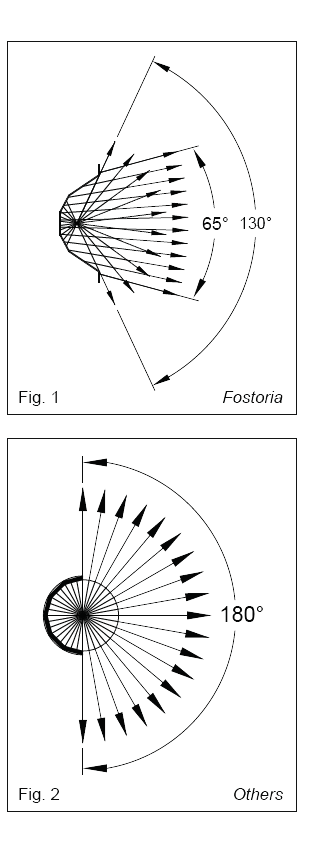

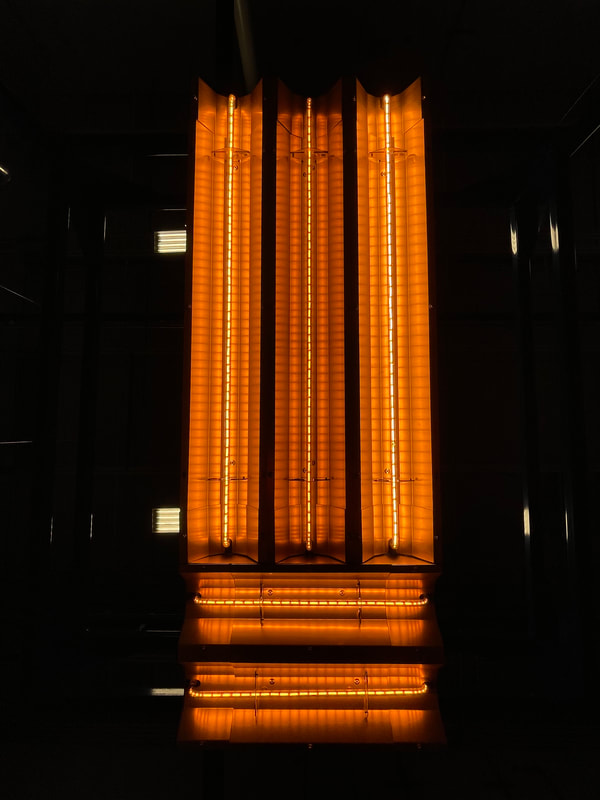

These standard hi-temp rated sections are designed to withstand oven temperatures up to 600°F. They can be installed inside convection ovens as a preheat or booster prior to convection curing of powders and paints.

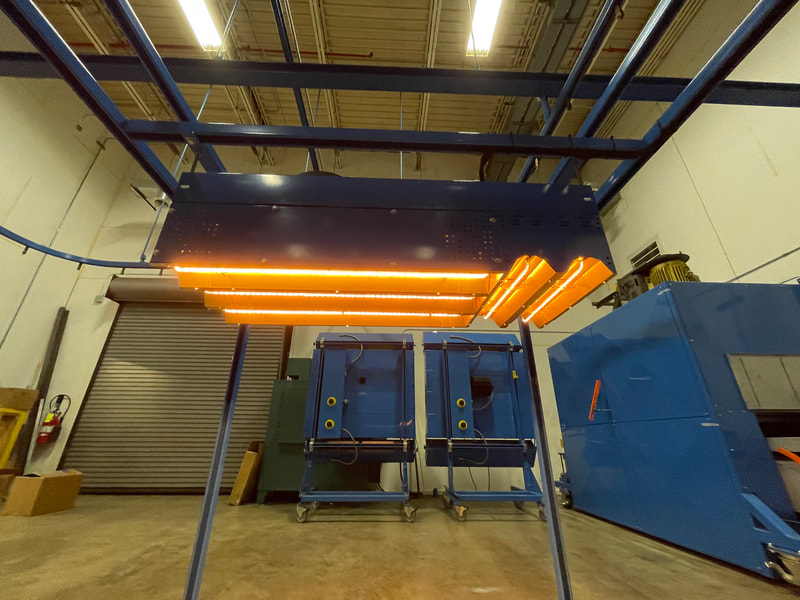

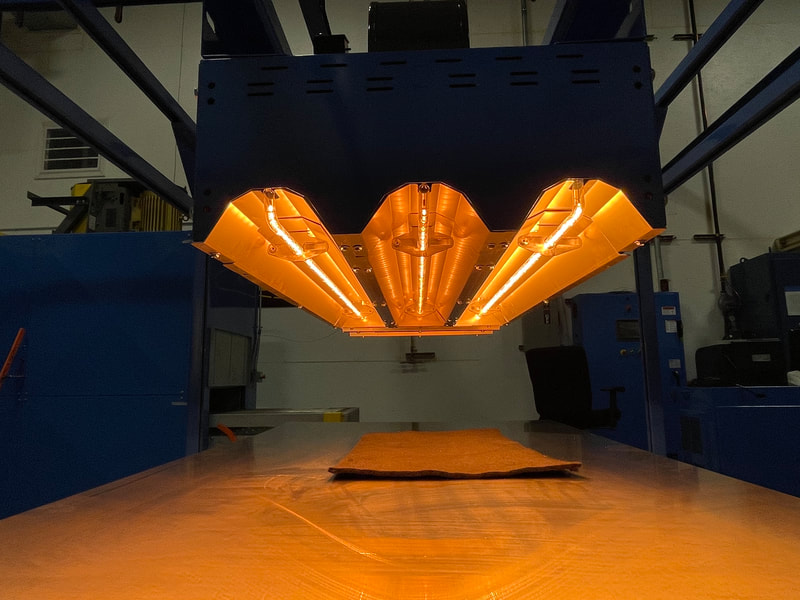

Hi-temp modular heat sections are also easily grouped to form IR banks for many applications that require the benefits of short, medium and long wave infrared.

Heater sections are also easily bolted and wired together (end-to-end to side-by-side) to form various oven configurations to fit the application.

These standard hi-temp rated sections are designed to withstand oven temperatures up to 600°F. They can be installed inside convection ovens as a preheat or booster prior to convection curing of powders and paints.

Hi-temp modular heat sections are also easily grouped to form IR banks for many applications that require the benefits of short, medium and long wave infrared.

Heater sections are also easily bolted and wired together (end-to-end to side-by-side) to form various oven configurations to fit the application.

|

SPECIFICATIONS

CLICK HERE for the full 900 Series catalog. |

|

Vertical Divider

|

Vertical Divider

|

|

Have a Question?

A Fostoria Application Engineer can assist you with sizing or any questions regarding section configuration that you may have.

A Fostoria Application Engineer can assist you with sizing or any questions regarding section configuration that you may have.