|

We’d love to hear from you. Fostoria remains dedicated to providing our customers with the most uniform heat possible and top-of-the-line infrared and process heat equipment.

Fostoria will design and build a system that will be customized to your application:

A Fostoria application engineer will be in touch shortly to discuss any questions or your specific heat requirements. |

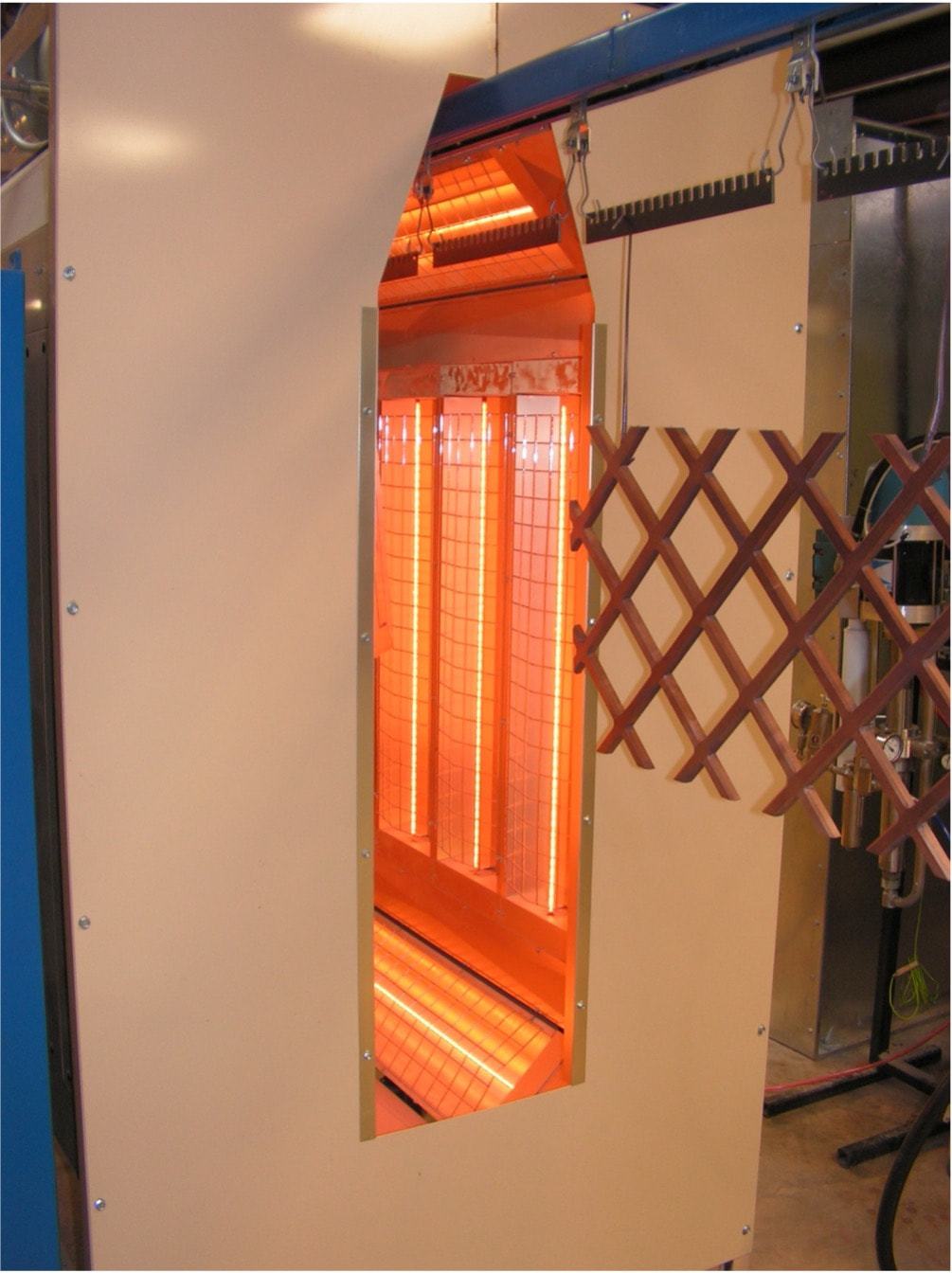

The secret to ensuring quality and resilience in your final product is all in the preparation and sealing of the wood. Most wood types are heat-sensitive and require specific temperature settings to avoid bleed or discoloration during the processing.

Infrared is ideal for drying wood and various processing applications because of its versatility, precision and control. Infrared waves can be directed to exact locations or zoned areas, which prevents overheating of other more sensitive areas. Unlike convection heat, there is no air movement required which eliminates the possibility of streaking, uneven drying or dust particles contaminating the paint. The IR waves can safely transmit energy to the surface of the wood and quickly cure or dry the sealant or paint and reduce moisture without penetrating or damaging the wood. Using a "zone controlled" system of electric infrared heat allows for the product to be heated to curing temperature faster, also increasing the production line speed. Popular applications that utilize infrared heat technology for wood processing, woodworking or furniture building include:

|

Copyright © 2024. Fostoria Infrared

All Rights Reserved.

Articles & Info | Legal Disclaimer

All list prices are suggested and shown in U.S. Dollars.

Pricing is subject to change without prior notice.

An equal opportunity employer.

Business Hours: M - F, 8:00am - 5:00pm EST | Closed on major U.S. holidays.

When ordering replacement parts, if your order qualifies for tax exempt status, contact factory ( 020821 )

1-800-682-3398 | www.tpicorp.com | answers@tpicorp.com

All Rights Reserved.

Articles & Info | Legal Disclaimer

All list prices are suggested and shown in U.S. Dollars.

Pricing is subject to change without prior notice.

An equal opportunity employer.

Business Hours: M - F, 8:00am - 5:00pm EST | Closed on major U.S. holidays.

When ordering replacement parts, if your order qualifies for tax exempt status, contact factory ( 020821 )

1-800-682-3398 | www.tpicorp.com | answers@tpicorp.com