|

CUSTOMIZED INDUSTRIAL OVENS

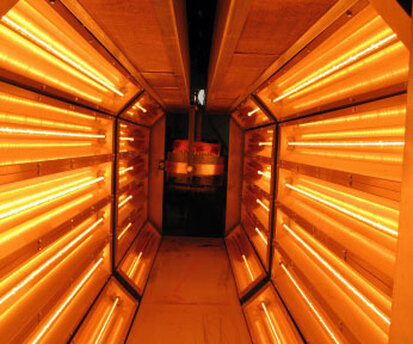

Fostoria is proudly one of the oldest and largest manufacturers of infrared process oven equipment. We understand that one size doesn't always fit all. Our advanced engineering capabilities and over 70 years of experience developing infrared technology allow us the ability to design and manufacture custom industrial ovens for virtually any application, heat source or specific process heat requirement. FREE PRODUCT TESTING FOR CUSTOM BUILDS Testing your product is one of the most critical steps in developing the best heating method and oven design for your application, and these tests are provided by Fostoria as a free service.. Fostoria prides itself on their state-of-the-art lab facility in Johnson City, TN. We are able to test using electric or gas infrared, high velocity hot air, convection heat (direct or indirect fired), or a combination of IR/convection. We make it our priority to fully understand your industry and specific application requirements. Many heat processing applications are forgiving and are able to work well with any infrared wavelength. However, there are many instances where choosing the right wavelength and temperature combination can make a tremendous difference in overall efficiency, speed of the process and even whether or not the process works. Our dedicated team will work with you to construct the best oven configuration for your heating process. Once product testing is complete and time/temperature curves are generated, a Fostoria Application Engineer will arrange for a consultation to review the findings and discuss the next steps of your project. |

|

INFORMATION NEEDED FOR TESTING:

(not all may apply)

The product will be returned to the customer for evaluation after testing has been completed. |

LET'S GET STARTED.

We look forward to hearing from you! An application engineer will be in touch to discuss your custom industrial oven build. |

|

INDUSTRIAL CONVEYORIZED OVENS

Industrial conveyor ovens utilize a variety of motion paths and conveyance configurations. This type of industrial oven is better suited for high-volume mass production applications. Since most conveyor ovens are automated, this allows for faster processing time without the time constraints a batch oven requires, such as loading, unloading, heat up and cool down times. These ovens are versatile and can be used in a wide variety of industries and heating applications

Fostoria's indexing or continuous industrial ovens can be customized to accommodate your specific size and load requirements. |

The main types of conveyors that are commonly used in industrial processing applications:

- flat wire belt - these belts are most popular and can be used in a wide variety of temperatures, product sizes and applications

- woven belt - this belt is customizable, available in a variety of configurations and while commonly used to move small parts, they can also handle higher load capacities

- chain - best suited for heavy loads due to their long-lasting durability and move the product or part by sliding or rolling

- roller - this type of conveyor system can be used in multiple applications and provides a stable surface for moving a wide range of products

- overhead trolley - the overhead conveyor saves floor space. It is commonly used to transport fragile products or heavy items that are unsafe to be handled by humans

- carousel - this conveyor type is simple and efficient. The oven is loaded and unloaded in the same spot, therefore only one operator of the machine is needed. The oven conveyor is versatile and can be loaded with various product sizes, weight capacities and quantities.

CUSTOM CONTROL PANELS

Fostoria designs, fabricates and programs control panels to accompany each industrial oven. Design and build is based upon your application and oven requirements for optimal functionality. In addition, many controls options are available.

We can provide all panel-related services , from design and layout; to sub-panel and panel assembly, low and high voltage wiring, component mounting and programing with integration to your machine or system.

All our panels:

- ETL listed

- Meet SCCR requirements

- NFPA 70 (NEC) and NFPA 79 electrical standards

- Category 2, 3 or 4 safety requirements

- Fostoria also provides PLC Programming, HMI operator interface design/programming, extensive CAD capability and VFD and Servo Drive options