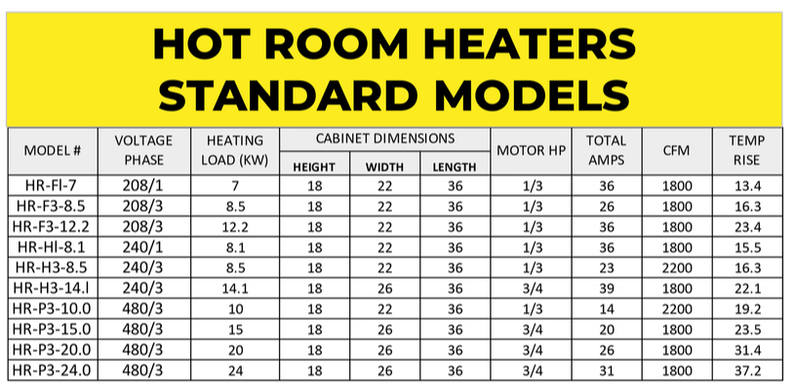

HR SERIES - HOT ROOM HEATERS

- Accelerate drying times

- Dehydrate products

- Simulate higher ambient temps

The Fostoria Hot Room Heater Series can heat rooms up to 150°F to bake, cure, dehydrate; or in general, to heat miscellaneous products or coatings requiring heat in a non-hazardous batch-type environment.

The Hot Room Heater can be used inside the room being heated, or located outside the room, with provisions for ducting inlet and outlet air.

- Accelerate drying times

- Dehydrate products

- Simulate higher ambient temps

The Fostoria Hot Room Heater Series can heat rooms up to 150°F to bake, cure, dehydrate; or in general, to heat miscellaneous products or coatings requiring heat in a non-hazardous batch-type environment.

The Hot Room Heater can be used inside the room being heated, or located outside the room, with provisions for ducting inlet and outlet air.

- 24 Volt time/temperature control with remote capability

- Replaceable filter

- Durable powder coat finish

- Stainless steel enclosed spiral fin elements

- Duct flanges at inlet and discharge

Fostoria application engineers can assist you with heater/model sizing for your application.

Vertical Divider

- high temperature rated, ball bearing motor; forward curved centrifugal blower; standard with airflow switch, temperature limit controls (manual and automatic resets) and lockable disconnect switch with fuse block.

- galvannealed 20 gauge heavy duty metal housing

- totally enclosed, finned tubular stainless-steel heating elements provide the benefits of closer temperature regulation, less chance of shock hazards, less susceptibility for short, easy service; and will better withstand physical abuse.

- capability of mounting for in-room use, or mounting at an external wall/ceiling, with the heat inlet/outlet ducted to/from the room. 1" duct flanges at inlet and discharge ends are standard, to provide for ducting on the unit.

- all models listed are designed for permanent mounting and hard wiring

- a typical hot room should be totally enclosed, with provisions made to keep air from escaping, other than the air being ducted through the heater itself when the unit is mounted outside the room. As always, insulation should be considered for walls and ceiling, to maximize energy, efficiency and heater performance.

Have a Question?