SEAMLESS INFRARED TECHNOLOGY

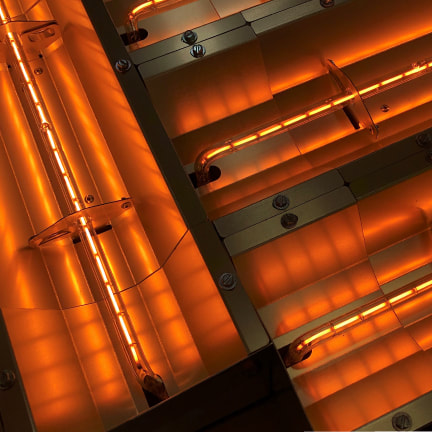

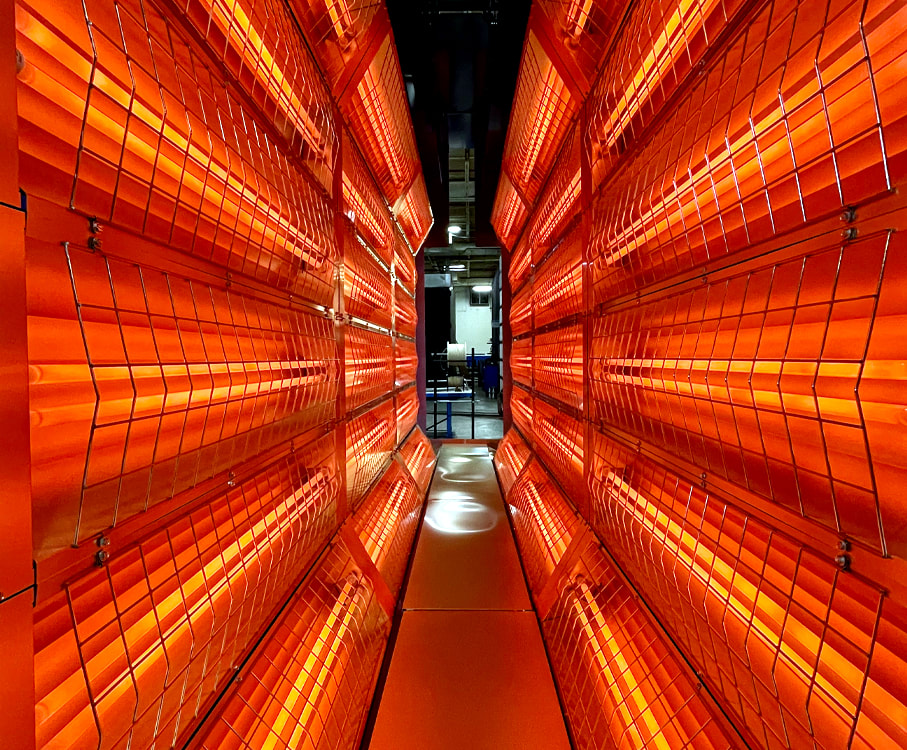

Our Seamless Infrared Technology showcases a 'bent lamp configuration', which allows these heating elements to be mounted end to end for seamless heating. Because of its optimal design concept, Seamless Infrared equipment is able to effectively heat products that need integrated zoning or large continuous heated areas. One of the primary applications for this equipment is for thermoforming lines for automotive interiors and exterior products.

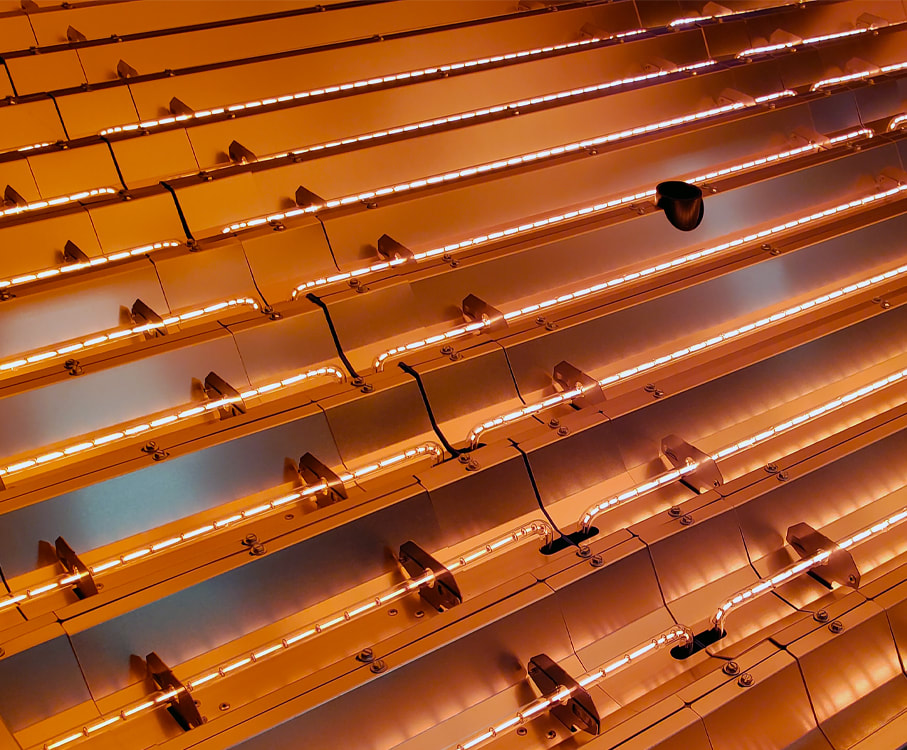

Fostoria’s Seamless Infrared contains a parabolic reflector, which delivers infrared energy across a 130-degree pattern, with the majority of the reflected infrared in a tighter 65-degree pattern. More energy can be delivered to the product with the parabolic shape.

The equipment can be used for any size product, and with its multiple zoning capabilities, very uniform temperatures can be achieved. With defined zoning, you can also create a heat profile that exactly matches the product heating requirements. The bent lamps provide instant on & off heat, which allows the product to be heated to an exact temperature with little chance of overheating.

Our Seamless Infrared Technology showcases a 'bent lamp configuration', which allows these heating elements to be mounted end to end for seamless heating. Because of its optimal design concept, Seamless Infrared equipment is able to effectively heat products that need integrated zoning or large continuous heated areas. One of the primary applications for this equipment is for thermoforming lines for automotive interiors and exterior products.

Fostoria’s Seamless Infrared contains a parabolic reflector, which delivers infrared energy across a 130-degree pattern, with the majority of the reflected infrared in a tighter 65-degree pattern. More energy can be delivered to the product with the parabolic shape.

The equipment can be used for any size product, and with its multiple zoning capabilities, very uniform temperatures can be achieved. With defined zoning, you can also create a heat profile that exactly matches the product heating requirements. The bent lamps provide instant on & off heat, which allows the product to be heated to an exact temperature with little chance of overheating.

Vertical Divider

This equipment utilizes integrated lamp support brackets for ease of lamp replacement, which allows the lamp to be installed and held in place by the brackets, allowing both hands to be free for the electrical connection of the lamp.

|

Vertical Divider

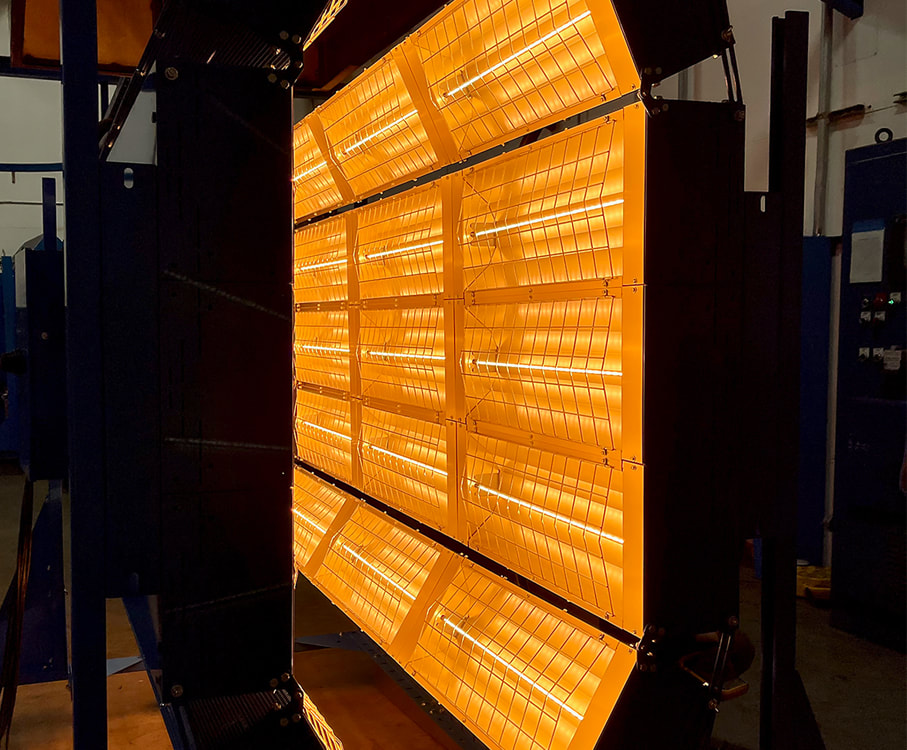

For some applications, it may be necessary to double the power density due to space considerations. For these special applications, Fostoria's individual heat banks can be equipped with two heat sources to double the watt density.

With higher power density you can achieve a faster heat up cycle in a smaller area. Cooling blowers are required to remove excess heat from the equipment. This is necessary to lengthen the life of the lamps and the oven equipment. For more information on this new technology, and the benefits of using infrared for your heating process, please contact us for the next steps in developing a technical solution for your application. |

|

Have a Question?