|

FOSTORIA’S TECH CENTER AND LAB TESTING FACILITY

Fostoria maintains a technical R&D facility and lab testing area, and we routinely perform FREE customer testing for a variety of potential oven applications. Customer product testing is a fundamental part in developing a process heat solution that best fits their application. With our years of experience and with the latest infrared technology, we embrace the opportunity to show our customers what we can do to improve their production and efficiency. Therefore, we have invested heavily in lab equipment, and that includes virtually all types of ovens (gas or electric), plus short-medium-long wave infrared emitters, convection models, hot-air impingement dryers; as well as other hybrid or unique oven equipment. In addition, the lab has an advanced data acquisition system, conveyor capabilities for processing parts, paint/powder booth, batch ovens, and other resources used in the daily testing of product. In almost all cases, the eventual oven design starts with testing at our facility, so feel free to CONTACT US today to discuss your application. Please refer to the video for an overview of our tech center and test lab capabilities. |

|

In some unique cases the testing process requires the testing to be performed at the customer’s location or other remote location. For these applications we have developed a small but powerful research and development oven. This oven is available for purchase and can be shipped quickly to your designated location.

|

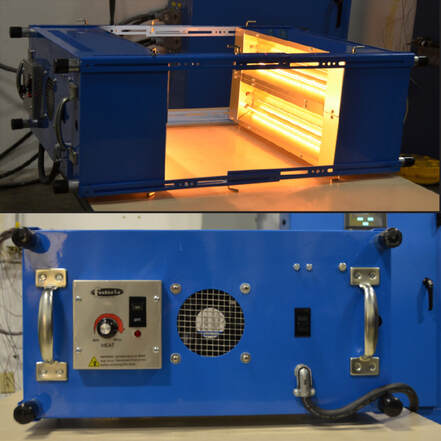

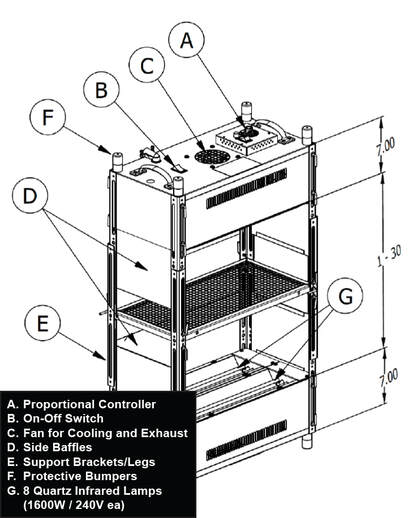

CONTROLS

Each of the two banks has a separate proportional controller, fan motor and on/off switch. When switched to the ON position, two of the four lamps energize. The potentiometer will regulate the other two lamps from zero to full output. A radiometer (optical pyrometer) is available from Fostoria that reads non-contact temperatures on the surface of the product, and can be purchased as an option to this test oven. Hand held radiometers are also excellent for reading surface temperatures. The built-in fan in each heater section removes heated air from the interior of the modular sections, to ensure safer operation and longer lamp life. CLICK HERE for the R&D Oven manual.

|

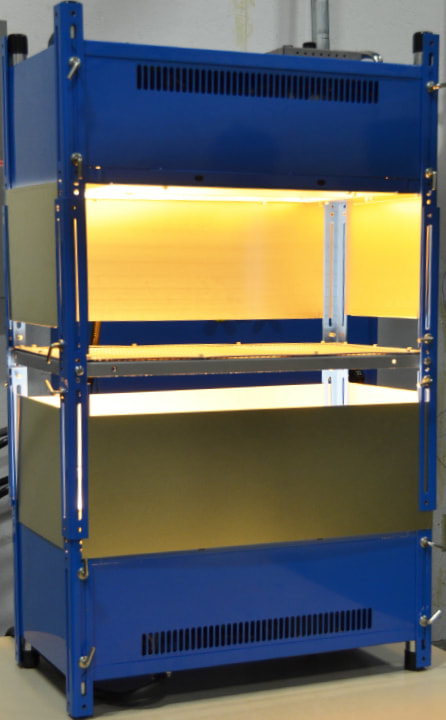

3-in-1 RESEARCH & LAB INFRARED OVEN

This versatile lab oven allows Fostoria customers to perform a variety of product testing in their own facility to supplement their research and development strategies. This oven can aid in project development by shortening the time needed for completion.

The main heat sections of the oven can be easily configured with the mounting brackets as shown in the photos below, and the arrangement will depend on how the product will eventually be presented into the oven. The banks can be opposed in an 11” x 22” design for heat from opposite sides; or be converted to an 11” x 44” or 22” x 22” pattern for one sided heat. The frame brackets allow heat sections in the opposing position to extend from 1” to 30” apart. Handles on the top allow for easy handling, and rubber feet prevent marring of table tops. The oven includes a total of (8) T-3 short-wave, clear quartz infrared lamps, which can be controlled in an infinite range to impinge short-medium-or long wave infrared on the product. Each lamp is 1600 watts, at 240 volt. Total electrical draw is 12.8 Kw (53.4 amps, 240 V, single phase) at full power. Each heater section has a 12-ft, #12/3 cable. Cable termination to the power source (by customer) can be made with a plug/receptacle or wired directly to a J-box with disconnect or other acceptable and safe device. |

Have a Question?

Get in touch with an application engineer to learn more about testing your product and R&D Lab Testing Oven possibilities.

Get in touch with an application engineer to learn more about testing your product and R&D Lab Testing Oven possibilities.