|

INFRARED SEAT OVENS & HEATERS

For the past 40 years, Fostoria has been developing and manufacturing equipment for the automotive seating industry. Through the years we have developed a variety of equipment to help solve wrinkling issues, or to relax trim prior to installation. To help remove excessive wrinkles and chatter on the sew lines, electric infrared was chosen because of its "instant-on" capability, energy efficiency, and its ability to focus heat on specific seat locations for precise periods of time. Seat ovens are designed to fit the profile of the seat and with multiple zone control, to maintain consistent and precise temperatures. The design uses both vertical and horizontal tungsten quartz lamps (short wavelength, T-3 lamps) with alternating angular beam reflectors. Temperatures range from 180° to 250°F and time cycles from 45 to 90 seconds. The instant responding T-3 lamps are automatically de-energized if the conveyor is stopped, preventing overheat damage to the seats. Radiometers can also be used to monitor temperatures at various locations on the seat. |

|

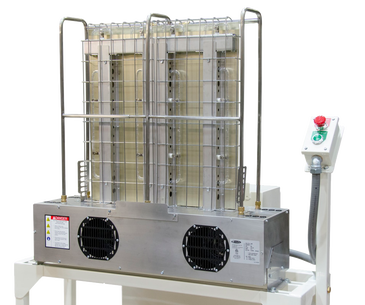

SEAT OVEN DESIGN This oven is typically designed to be mounted over an existing flat belt conveyor line. The oven may have one or more heat stations, depending on whether the conveyor belt is continuous or indexing. The controls can also vary depending on the way the seat cushion is processed. The oven is highly effective because of the shape of the oven in relationship to the seat cushion. Hot air can also be introduced with infrared in some cases for optimum results. |

ST-1 MODEL

ST-1 MODEL

ST SERIES SEAT TRIM HEATERS

Fostoria’s exclusive line of PREWARMING automotive seat trim heaters. The ST Series is used in seat plants to heat and relax trim prior to installation on the seat, and de-wrinkle the trim for an improved appearance.

ST-1 MODEL: Heats trim for open and closed backed bucket seats and cushions, and 40% seat backs and cushions.

SPECIFICATIONS

CONTROLS

Fostoria’s exclusive line of PREWARMING automotive seat trim heaters. The ST Series is used in seat plants to heat and relax trim prior to installation on the seat, and de-wrinkle the trim for an improved appearance.

ST-1 MODEL: Heats trim for open and closed backed bucket seats and cushions, and 40% seat backs and cushions.

SPECIFICATIONS

- All heaters incorporate instant ON/OFF shortwave infrared T-3 quartz lamp emitters, arranged both horizontally and vertically, to impinge heat on all areas of the trim. These IR lamps have an average rated life of 5000 hours.

- Gold anodized aluminum reflectors direct heat to the front, sides, top and back of the trim.

- A blower also is supplied and is mounted in the base. It will blow air up into and thru the perforated reflectors, adding convection air in combination with the direct IR heat, resulting in very uniform heat.

- Two SS tubular stanchions hold the trim in place, and are adjustable up/down and left/right.

- Entire heater section can be tilted, making it ergonomically friendly.

- 6.6 KW, all voltages; 54” max. overall height

CONTROLS

- Panel is a NEMA 1 enclosure mounted to the stand. All factory pre-wired and connected to the heater section. Customer simply brings supply wiring to the disconnect switch in the panel.

- Siemens PLC small block with analog inputs/outputs. The PLC controls the following: An infinitely variable SCR power controller to regulate the heat output; up to (3) product recipes, with each recipe containing operating parameters that include:

- Percent output of the infrared emitters for High Heat and Low Heat settings

- High heat time cycle

- Batch time cycle for the total time the heater is energized.

- Once recipes are programmed, simply place the trim on the heater and press the Cycle Start button.

|

|

|

ST-2 MODEL: Heats trim on front 60% seat backs and cushions.

SPECIFICATIONS

SPECIFICATIONS

- Similar specifications as the ST-1 model, except wider (and with 3 stanchions vs 2) to accommodate the larger 60% trim sizes.

- 7.2 KW, all voltages, 54” max. overall height

Have a Question?