THERMOFORMING COMPRESSION EQUIPMENT

Fostoria thermal compression system capabilities have greatly expanded in recent years. We have developed a wide variety of equipment and have partnered with suppliers to offer a full turnkey solution for compression applications. This equipment is typically used by Tier One suppliers in the automotive industry, or for thermal compression in markets such as aircraft components and office wall panels. Our systems can be designed for compression or vacuum forming processes.

Fostoria thermal compression system capabilities have greatly expanded in recent years. We have developed a wide variety of equipment and have partnered with suppliers to offer a full turnkey solution for compression applications. This equipment is typically used by Tier One suppliers in the automotive industry, or for thermal compression in markets such as aircraft components and office wall panels. Our systems can be designed for compression or vacuum forming processes.

|

COMPRESSION EQUIPMENT

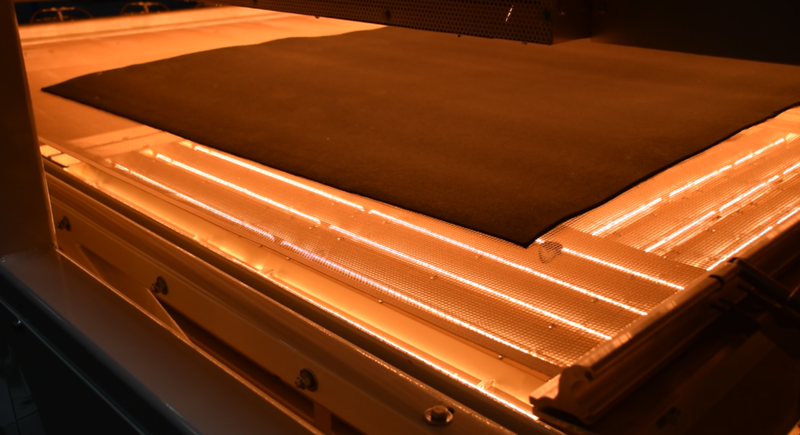

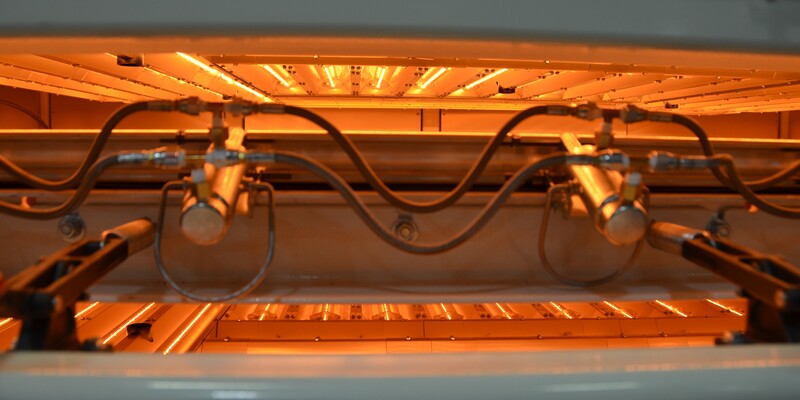

This design allows for the product to be auto loaded onto the oven conveyor belt. The product indexes into a two-station infrared oven with moldable zones for precise heating. It may not always be necessary to have a two-station oven. One or two stations are determined by time cycle and product temperature requirements. Once the product has been heated, it moves onto a transfer conveyor and into the press. The transfer conveyor eliminates the need for operators to handle the hot part, and assists in decreasing the cycle time. Some applications have two different types of material which need to be heated at different temperatures. Depending on the types of material, it may require two types of heating processes. |

|

|

|

VACUUM EQUIPMENT

Vacuum form systems are typically loaded utilizing pull to length and cutter equipment. The heating process can be either infrared or contact heating. Oven systems are designed with multiple zones to allow for heat profiling of the product. This equipment is designed with a heavy duty transfer conveyor for depositing the product over the top of the vacuum tool. Product recipes are integrated into the PLC System to allow the operator to easily select recipes from one product to another. Precise product temperature control is critical. |

MANUALLY LOAD/UNLOAD THERMOFORMING OVENS

Single or dual shuttle tray conveyor systems are typically used for our manually load/unload thermoforming ovens, and their unique shuttle operation allows the operator to easily load/unload product. Often purchased to improve productivity, they simplify handling by "shuttling" a warm sheet out with each cold sheet put in. The ovens feature continuous closed loop sensors to assure uniform temperatures. Advanced oven models incorporate an exclusive pneumatic "trap" to clamp the material on four sides, thus preventing dimensional changes prior to forming. Common applications for shuttle ovens include: door panels, dashboards, wheel wells, and under the body panels. As with all Fostoria ovens, these are individually engineered and built to the specific requirements of the application.

Single or dual shuttle tray conveyor systems are typically used for our manually load/unload thermoforming ovens, and their unique shuttle operation allows the operator to easily load/unload product. Often purchased to improve productivity, they simplify handling by "shuttling" a warm sheet out with each cold sheet put in. The ovens feature continuous closed loop sensors to assure uniform temperatures. Advanced oven models incorporate an exclusive pneumatic "trap" to clamp the material on four sides, thus preventing dimensional changes prior to forming. Common applications for shuttle ovens include: door panels, dashboards, wheel wells, and under the body panels. As with all Fostoria ovens, these are individually engineered and built to the specific requirements of the application.

For some thermoforming applications with thick and “fluffy” materials (such as non-wovens), the penetrating capability of high velocity air will, in most cases, produce the fastest possible heat cycles.

DESIGN FEATURES OF FOSTORIA HIGH VELOCITY OVENS:

DESIGN FEATURES OF FOSTORIA HIGH VELOCITY OVENS:

- Heavy duty aluminized steel panels with up to 6” of insulation

- Energy source variety, Fostoria oven systems can utilize gas or electric heat sources

- Air nozzles are designed to impinge an even, direct path of air flow, to provide thorough and uniform heating.

- Spacing and sizing of these nozzles are precisely engineered for the application

- Access doors for ease of maintenance. Doors are hinged in a manner that they serve as explosion relief for safety purposes

- Complete closed-loop control system to maintain the continuous, efficient operation of the oven. This control automatically modulates air temperatures to maintain a given set temperature. Additional controls such as an interlock disconnect switch, purge timer, auto ignition, overload protection and flame proof are provided to meet all safety and operational requirements

- PLC control systems are also available for this type of equipment

Have a Question?