|

PROCESS HEATING & WARMING OVENS

Our warming oven systems are available for a variety of heating processes. The ovens can operate at temperatures ranging from 100° F to 450° F and can be designed to your application. This diverse product line can be adapted for multiple applications, including but not limited to:

Fostoria has developed a variety of oven systems to meet specific warming/heating requirements, minimize space and increase production speeds on assembly lines. We welcome the opportunity to consult with you regarding your application. |

CONTAINER OVENS

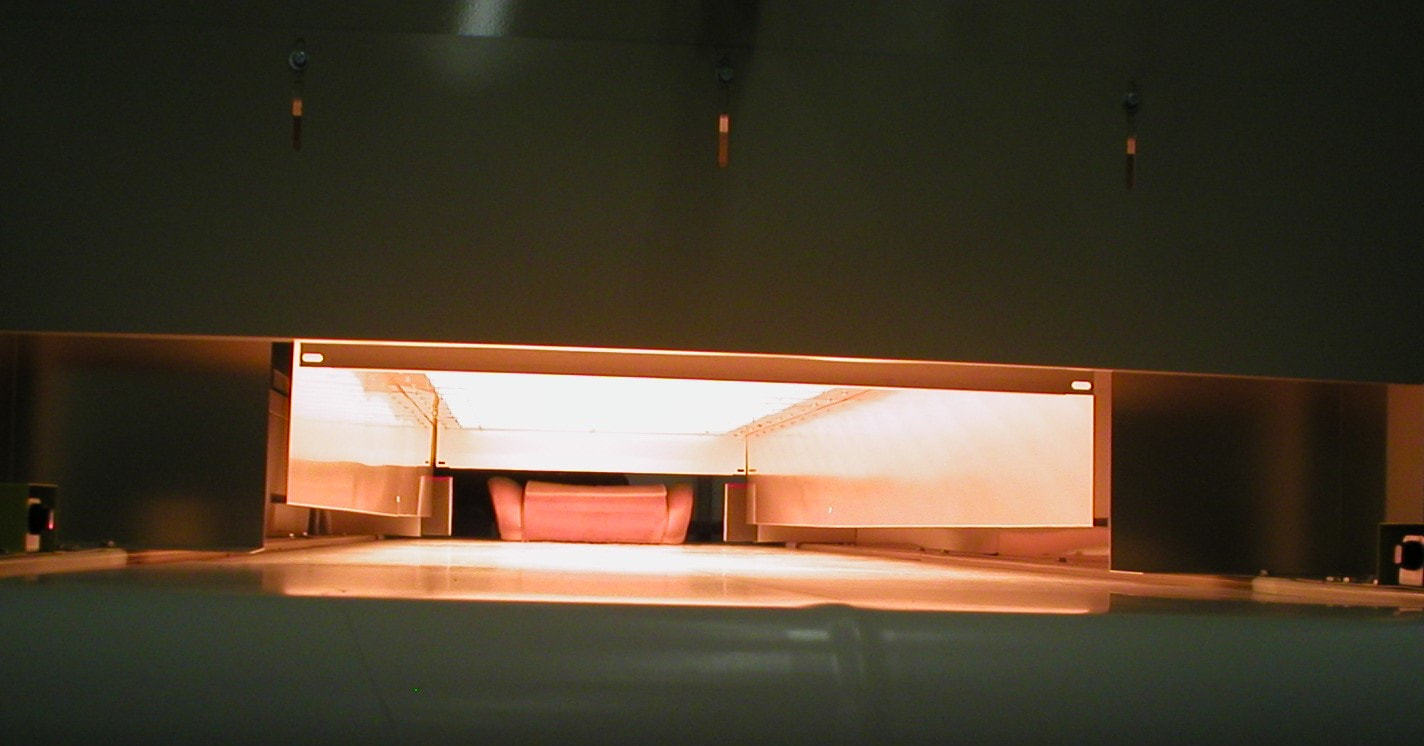

This oven is typically used to warm/heat automotive components such as wire harnesses or body trim that are shipped inside of a container.

The container is rotated inside the heating chamber to allow the hot air to enter into the pockets to heat the product. When ready to start unloading the container, the operator will rotate the container 90° to allow access to the harness or trim. The load and unload of the equipment is done on the production line side of the vehicle. A rapid-roll door can be installed on the load / unload side to improve on overall heating efficiency.

For some operations we add an index conveyor to this design. This system will have multiple heat chambers. The heat chambers will be completely open in between, to allow free movement for the container from one station to the next. The number of heat stations is determined by the overall production requirements..

If the equipment cannot be placed near the production line, the container ovens can be designed to heat the product “offline”. These locations are typically a warehouse or receiving area. For this application the backside of the equipment is closed off and can be placed close to a wall if required.

This oven is typically used to warm/heat automotive components such as wire harnesses or body trim that are shipped inside of a container.

The container is rotated inside the heating chamber to allow the hot air to enter into the pockets to heat the product. When ready to start unloading the container, the operator will rotate the container 90° to allow access to the harness or trim. The load and unload of the equipment is done on the production line side of the vehicle. A rapid-roll door can be installed on the load / unload side to improve on overall heating efficiency.

For some operations we add an index conveyor to this design. This system will have multiple heat chambers. The heat chambers will be completely open in between, to allow free movement for the container from one station to the next. The number of heat stations is determined by the overall production requirements..

If the equipment cannot be placed near the production line, the container ovens can be designed to heat the product “offline”. These locations are typically a warehouse or receiving area. For this application the backside of the equipment is closed off and can be placed close to a wall if required.

CONVEYORIZED WARMING/HEATING OVENS

Conveyor warming/heating ovens can be equipped with infrared, infrared with hot air impingement or with medium velocity hot air only. Depending on the application, we have the heating solution that will maximize your production needs. We offer a large variety of conveyor belt types and sizes, that are also tailored to the application. Closed loop temperature controls and temperature read outs are available. An exhaust system can also be added if required.

Conveyor warming/heating ovens can be equipped with infrared, infrared with hot air impingement or with medium velocity hot air only. Depending on the application, we have the heating solution that will maximize your production needs. We offer a large variety of conveyor belt types and sizes, that are also tailored to the application. Closed loop temperature controls and temperature read outs are available. An exhaust system can also be added if required.

|

|

CAROUSEL OVENS

The carousel oven design allows for multiple parts, including wiring harnesses, to be heated in one oven chamber at the same time. For wiring harness applications, the container is located beside the oven. The operator will remove a warm wiring harness from the oven and replace it with one from the container. By separating the harnesses from the container, the oven can heat the parts more efficiently and thoroughly. It improves the pliability of the wiring harness, making it more ergonomically friendly. Production requirements and size of the wiring harness will determine the height and size of the oven system. Another advantage of a vertical carousel oven is that it requires less production floor space. The baskets can be supplied with a divider if required and can be modified for a variety of products. |

Have a Question?